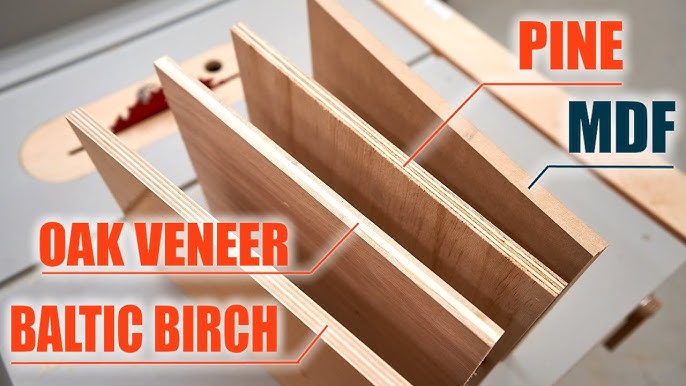

When it comes to choosing the right material for your next project, you might be stuck between birch plywood and MDF. Both are popular options, but which one truly fits your needs?

Understanding their differences can save you time, money, and frustration. You’ll discover the key features, pros, and cons of birch plywood and MDF. By the end, you’ll feel confident about making the best choice for your furniture, cabinetry, or DIY work.

Ready to find out which material suits your project perfectly? Let’s dive in!

Birch Plywood Basics

Birch plywood is a popular material in woodworking and construction. It offers strength, durability, and a smooth finish. Understanding its basics helps to choose the right material for your project.

This section explains the material, how it is made, and where it is commonly used.

Material Composition

Birch plywood consists of thin layers of birch wood. These layers are called veneers. The veneers are glued together with the grain of each layer running opposite to the next. This cross-grain pattern adds strength and stability. Birch wood is light-colored and has a fine grain. It gives the plywood a clean and smooth surface.

Manufacturing Process

The process starts by peeling birch logs into thin sheets. These sheets are dried to remove moisture. Then, glue is applied between the layers. The layers are pressed under high heat and pressure. This binds the layers firmly. The plywood is then cut into standard sizes. Quality checks ensure there are no defects.

Common Uses

Birch plywood is used in furniture making. It is popular for cabinets, shelves, and tables. It also works well for interior walls and ceilings. Its smooth surface makes it easy to paint or varnish. Woodworkers like it for toys and craft projects. Birch plywood is strong enough for flooring underlayment too.

Mdf Essentials

MDF, or Medium-Density Fiberboard, is a popular wood product used in many projects. It offers a smooth surface and consistent texture. Understanding its key features helps in choosing the right material for your needs.

MDF stands out for its unique blend of wood fibers and strong bonding. This makes it different from natural wood or plywood.

Material Composition

MDF is made from tiny wood fibers. These fibers come from softwood and hardwood trees. They mix with resin and wax to hold them together. The result is a dense, smooth board. This board has no knots or grain like natural wood.

Manufacturing Process

The fibers get steamed and broken down into fine pieces. Then, they mix with glue and wax. The mixture gets pressed under heat and pressure. This creates thick, flat panels. The process creates a strong and uniform board. It also allows MDF to be cut and shaped easily.

Common Uses

MDF is often used for furniture, cabinets, and shelves. It works well for painting or veneering. It is also common in molding and trim work. MDF’s smooth surface helps achieve a clean finish. It is less expensive than solid wood or plywood.

Strength And Durability

Strength and durability are key factors when choosing materials for furniture and construction. Birch plywood and MDF both offer unique benefits. Understanding their differences helps you pick the right one for your project. Let’s explore how they perform in strength and durability.

Load-bearing Capacity

Birch plywood has a strong load-bearing capacity. Its layers of wood veneer are glued together with the grain running in different directions. This gives it excellent strength and stability. It can support heavy weights without bending or breaking easily.

MDF is made from wood fibers pressed with resin. It is dense but not as strong as plywood. It can hold moderate weights but may sag under heavy loads. For strong structures, birch plywood is a better choice.

Resistance To Wear

Birch plywood resists wear well. Its surface is tough and can handle daily use. Scratches and dents are less common on plywood.

MDF has a smooth surface but is softer. It can get damaged faster by impacts or abrasion. Over time, MDF may show signs of wear more clearly.

Moisture Resistance

Birch plywood has better moisture resistance than MDF. It handles humidity and minor spills without warping quickly. Some plywood types are treated for extra water resistance.

MDF absorbs water easily. It swells and loses shape if exposed to moisture. Special moisture-resistant MDF exists but costs more. For damp areas, birch plywood is more reliable.

Workability And Finish

Workability and finish are key factors in choosing between birch plywood and MDF. These qualities affect how easy the materials are to handle and how good the final product looks. Both materials have unique traits that influence cutting, sanding, painting, and joining. Understanding these differences helps in picking the right one for your project.

Cutting And Shaping

Birch plywood cuts cleanly with sharp tools. It holds its shape well due to its layered structure. Its edges are strong but may splinter if cut too fast. MDF is softer and easy to cut. It shapes smoothly without splinters. However, MDF dust is fine and needs careful handling. Both materials work well with saws and routers, but tool sharpness is important.

Sanding And Painting

Sanding birch plywood reveals a smooth wood grain. It requires light sanding before painting or staining. The finish looks natural and warm. MDF has a smooth, even surface from the start. It sands easily but can absorb paint quickly. Using a primer on MDF prevents uneven paint spots. Both accept paint well, but MDF needs sealing for best results.

Joining Techniques

Birch plywood holds screws and nails firmly. It is strong enough for glue joints too. Pre-drilling holes can stop splitting. MDF is dense and can split if not handled carefully. Screws need pilot holes and sometimes special fasteners. Glue works well on MDF, especially with clamps. Using the right joining method keeps both materials secure and lasting.

Cost Comparison

Comparing the cost of birch plywood and MDF helps you choose the right material for your project. Price affects both your budget and the value you get over time. Understanding the differences can save money and improve your results.

Material Price

Birch plywood is usually more expensive than MDF. It is made from thin layers of birch wood glued together. This process costs more than making MDF from wood fibers and resin. MDF has a lower price, making it popular for budget projects. You get a smooth surface with MDF, but it is less strong than birch plywood.

Long-term Value

Birch plywood lasts longer and handles wear better. Its strength makes it good for furniture and flooring. MDF can swell or break when exposed to water. Over time, birch plywood may save money by needing fewer repairs. MDF might need replacement sooner, increasing overall costs.

Environmental Impact

Understanding the environmental impact of Birch plywood and MDF helps make better choices. Both materials come from wood, but their production and disposal affect nature differently. Knowing these differences can guide eco-friendly decisions.

Sustainability

Birch plywood is made from thin layers of birch wood glued together. Birch trees grow relatively fast and can be replanted easily. This makes birch plywood more sustainable than some other woods. MDF, or medium-density fiberboard, is made from wood fibers, glue, and resin. It often uses wood waste from sawmills, which helps reduce wood waste. However, the resins in MDF sometimes contain chemicals that may harm the environment. Birch plywood generally has a lower environmental footprint during production.

Recyclability

Birch plywood can be recycled or reused in many ways. It breaks down naturally if composted, without releasing harmful chemicals. MDF is harder to recycle because of the glue and resin inside. These chemicals can make the material unsafe for composting or burning. MDF often ends up in landfills, where it takes a long time to break down. Choosing birch plywood helps reduce waste and supports recycling efforts.

Best Applications

Choosing the right material depends on the project type. Birch plywood and MDF each have strengths. Understanding their best uses helps create durable and attractive items. The following sections explain where each material works best.

Furniture

Birch plywood suits furniture that needs strength and light weight. Chairs, tables, and shelves benefit from its durability. It resists warping and holds screws well. MDF works for painted furniture with smooth surfaces. It shapes easily for curves and details. MDF is less strong but good for indoor use.

Cabinetry

Birch plywood is ideal for kitchen and bathroom cabinets. It handles moisture better than MDF. Cabinets made from birch plywood last longer in humid areas. MDF is good for cabinet doors and panels. It offers a clean, smooth finish for paint. MDF is best for dry areas and less heavy use.

Decorative Projects

MDF excels in decorative projects. Its smooth surface is perfect for painting and veneering. It cuts easily into detailed shapes and designs. Birch plywood can also be used but may show wood grain. For projects needing strength and natural look, birch plywood is better. MDF fits well for indoor decorations with fine details.

Choosing The Right Material

Choosing the right material for your project is important. Birch plywood and MDF both have their strengths. Picking the best one depends on what you need. Consider your project’s demands, your budget, and how the finished product should look.

This helps you make a smart choice. Let’s explore these key points in detail.

Project Requirements

Think about what your project needs. Birch plywood is strong and holds screws well. It works great for furniture and shelves. MDF is smooth and easy to paint. It fits well for indoor decorations and cabinets. Check if the material needs to handle weight or moisture. Choose the one that fits your project’s demands best.

Budget Considerations

Price plays a big role in choosing materials. MDF is usually cheaper than birch plywood. It is a good choice for tight budgets. Birch plywood costs more but lasts longer. Spend more if you want strength and durability. Balance cost with the quality you need.

Aesthetic Preferences

Look at how the material looks. Birch plywood shows natural wood grain. It adds warmth and character to the project. MDF has a smooth, uniform surface. It is perfect for painting and finishing. Choose birch plywood for a natural wood feel. Pick MDF for a clean, painted look.

Frequently Asked Questions

What Are The Main Differences Between Birch Plywood And Mdf?

Birch plywood consists of layered birch veneers, offering strength and durability. MDF is made from compressed wood fibers, providing smoothness but less strength. Plywood resists moisture better, while MDF is easier to paint and shape. Both have unique uses depending on project needs.

Which Is Better For Furniture: Birch Plywood Or Mdf?

Birch plywood is better for furniture needing strength and durability. It supports heavy loads and resists warping. MDF is ideal for decorative pieces requiring smooth surfaces and intricate shapes. Choose plywood for structural uses, and MDF for painted or detailed finishes.

How Does Moisture Resistance Compare Between Birch Plywood And Mdf?

Birch plywood resists moisture better due to its layered wood construction. MDF absorbs water easily, causing swelling and damage. For humid or wet environments, plywood is more suitable. MDF should be sealed properly if exposed to moisture to prevent deterioration.

Can Birch Plywood And Mdf Be Painted Equally Well?

MDF has a smoother surface, making it easier to paint without imperfections. Birch plywood may show wood grain but can be painted with proper priming. Both materials accept paint well, but MDF often requires less preparation for a flawless finish.

Conclusion

Birch plywood offers strength and a smooth finish for many projects. MDF is cheaper and easy to shape but less durable. Choose birch plywood for lasting furniture and cabinets. Pick MDF for indoor items and quick fixes. Both have good uses depending on your needs.

Understanding their differences helps you make smart choices. Quality and budget matter most in the end.

Recent Posts

Many people wonder if they can safely burn firewood that might have termites. It's a common question because nobody wants to damage their home or start a fire that's not safe. The good news is,...

It’s pretty common for folks to wonder, Can You Hear Termites Eating Wood? Warning Signs can sometimes be sneaky, and for those new to spotting them, it might feel a little tricky. You might be...